JPPL Series

CORROSION RESISTANT POLYPROPYLENE CENTRIFUGAL PUMPS

Single stage, End suction back pull out type centrifugal process pump

Our Centrifugal Process Pumps are one of the most preferred hydraulic pumps for industrial, as well as domestic use. Due to the high-quality impellers installed in these pumps, they generate a massive centrifugal force which provides an immense thrust to push liquids through the pipes. From basic applications like drip irrigation to handling volatile and abrasive chemicals, our centrifugal pumps can excel on all frontiers.

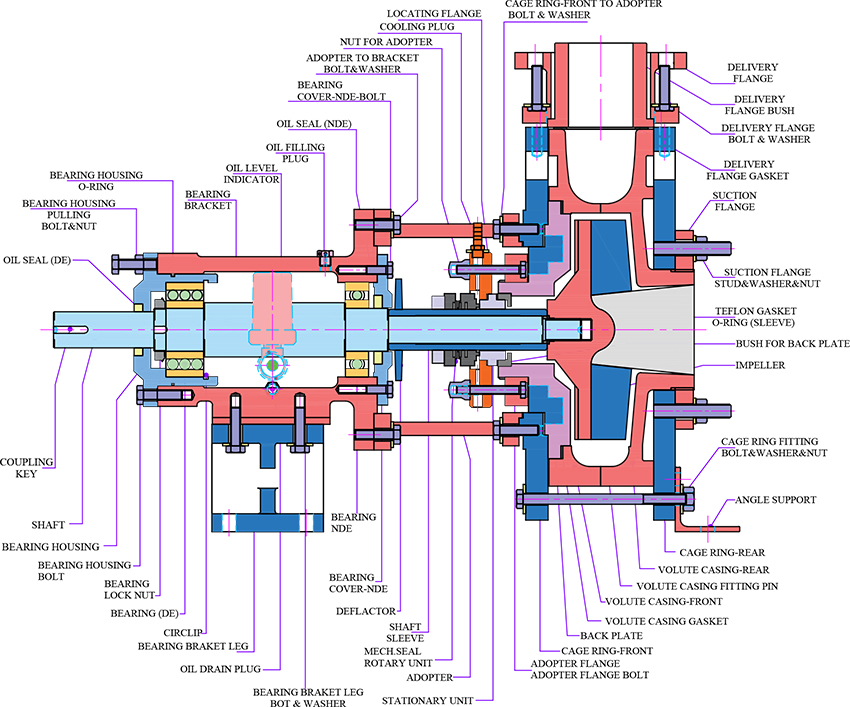

PUMP CONSTRUCTION

Volute Casing

Top centerline discharge, self venting volute casing which is formed out of injection moulded polypropylene

Ball Bearings

Inboard bearing is pressed on shaft and free to float axially in frame – carries radial load only. Outboard double row ball bearing is shouldered and locked on shaft with lock-nut and washer, and in bearing housing to carry radial and any unbalanced thrust load. All bearing fits are precision bored.

Backplate

Made of thick-walled solid injection and moulded polypropylene

Adopter

Facilities maintenance without disturbing Bearing Block and Shaft

Sleeve

Shaft sleeve of different material depending on the compatibility of the liquid to be handled

Mechanical Seal / Gland Packing

Pumps are fitted with either mechanical seal or gland packing depending on the conditions of service.

Shaft

Designed for maximum 0.05 mm deflection at mechanical seal. Available in EN / Stainless steel.

Impeller

All impellers are precision moulded, light in weight, semi-open construction with large, contoured flow passages for maximum handling of the liquid

Bearing Frame

Constructed from Heavy Cast Iron and precisely designed for no shaft deflection of more than 0.05 mm, and contains large oil reservoir

Cage Ring

Lends good mechanical strength to the casing in line with JEE’s design philosophy

Features

- Designed To Suit Extremely Corrosive Duties In The Process And Chemcial Industries

- Suitable For Continuous Service

- Self Venting Type Casing

- Large Capacity Transfer Pumps

- Dynamically And Hydraulically Balanced Impeller With Aerodynamic Profile Vanes

- Ideal For Bulk Transfer Of Acidic Effluents For Big Process Plants

- Pump Casing Installed With External Metal Ring For Construction Stability

- Temp. Range Up To 120*C

APPLICATIONS

| Effluent treatment plants | Dyes and intermediate steel rolling mills | All types of industrial application |

| Filter press feeding | Slurry transfer | Ceramic, ETP & STP |

| Paper & Pulp | Sugar & food | Eva-operator and scrubber application |

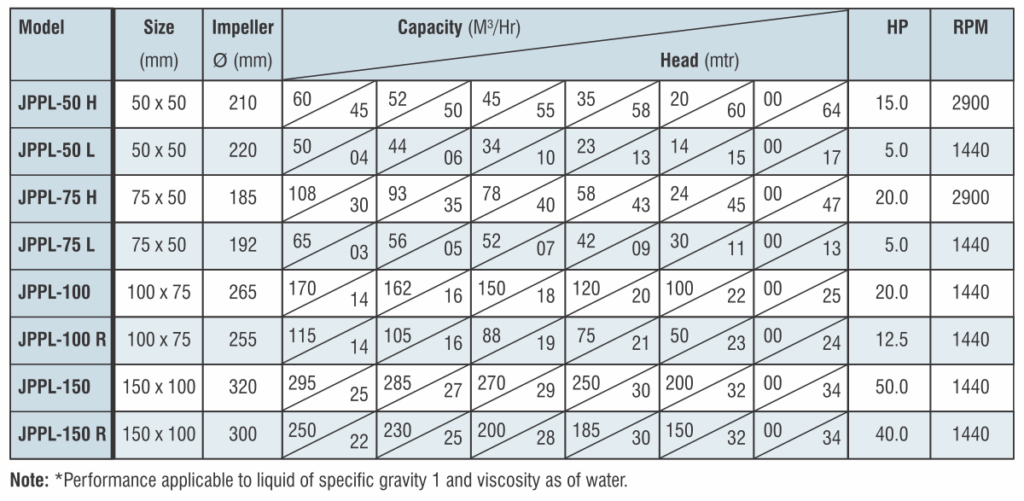

PERFORMANCE CHART

Operating Data

| Capacity | Up to 300 m³/hr |

| Head | Up to 65 Mtr. |

| Discharge Size | 50 mm to 100 mm. |

| Temperature | Up to 80°C |

| Speed | Up to 3500 rpm |

| Pressure | Up to 6.5 kg/cm2 |

| M.O.C. | PP, UHMWPE |